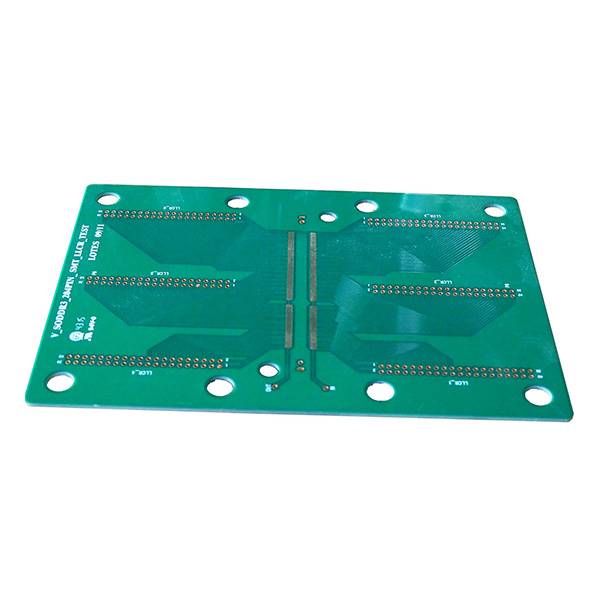

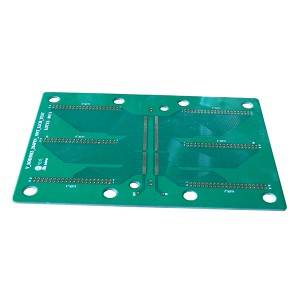

Gasar PCB Manufacturer

3 oz solder mask toshe ENEPIG babban allon jan karfe

Babu daidaitattun ma'anar ma'anar PCB mai nauyi, yawanci idan kauri na jan karfe ya fi 30z.

An ayyana allon a matsayin allon jan karfe mai kauri.

Ana amfani da PCBs masu nauyi da yawa a cikin Wutar Lantarki da Tsarin Samar da Wuta inda akwai babban buƙatu na yanzu ko yuwuwar harbi da sauri na kuskuren halin yanzu. Ƙarfafa nauyin jan ƙarfe na iya juya allon PCB mai rauni zuwa ingantaccen, abin dogaro, kuma dandali na wayoyi masu ɗorewa kuma yana ƙin buƙatar ƙarin farashi mai tsada da kayan haɓaka kamar Heat nutse, magoya baya, da sauransu.

M jan karfe allon yi: lokacin farin ciki allon jan karfe yana da mafi kyau tsawo yi, ba'a iyakance ta da aiki zafin jiki, high narkewa batu za a iya amfani da oxygen hurawa, low zafin jiki ba gaggautsa da sauran zafi-narke waldi, da kuma wuta rigakafin, nasa ne ga wadanda ba. - kayan konawa. Faranti na Copper suna samar da wani ƙarfi, mara guba, shafi mai wuce gona da iri, har ma a cikin yanayin yanayi mara kyau.

Amfanin farantin jan karfe mai kauri: Ana amfani da farantin ƙarfe mai kauri sosai a cikin kayan aikin gida daban-daban, samfuran fasaha, soja, likitanci da sauran kayan lantarki. Yin amfani da farantin ƙarfe mai kauri mai kauri yana tsawaita tsawon rayuwar sabis na hukumar da'ira wanda shine ginshiƙi na kayan aikin lantarki, kuma a lokaci guda, yana da matukar taimako don sauƙaƙe ƙarar kayan aikin lantarki.

Ƙirƙirar PCBs Copper Copper

Duk wani masana'anta na PCB, ko mai gefe ɗaya ko mai gefe biyu yana kunshe da etching tagulla don cire tagulla da ba'a so da dabarun plating don ƙara kauri zuwa jiragen sama, pads, da burbushi da Plated-Ta hanyar ramuka (PTH). Ƙirƙirar PCBs na Copper Copper yayi kama da ginin FR-4 PCBs na yau da kullum amma suna buƙatar fasaha na musamman da etching da electroplating wanda ke ƙara kauri daga saman allon ba tare da canza ƙidayar Layer ba. Allolin saman ƙasa mai kauri suna da ikon ɗaukar ƙarin ma'aunin tagulla saboda ƙwararrun dabaru waɗanda suka haɗa da sauri mai sauri, plating da kai, da banbance ko karkace etching.

Hanyar etching ta al'ada ba ta aiki ga PCBs mai nauyi na Copper kuma yana haifar da layukan da ba su dace ba da kuma abubuwan da ba su dace ba. Muna amfani da dabarun plating na ci-gaba don samun layuka madaidaiciya da ingantattun tabo mai kyau tare da ƙananan yankewa. Tsarin mu na ƙara plating yana rage juriyar alamun jan ƙarfe ta haka yana haɓaka ƙarfin sarrafa zafi da juriya don damuwa na thermal.

Ragewar juriya mai zafi yana inganta ƙarfin watsar da zafin da'irar ku ta hanyar haɗuwar zafi, gudanarwa, da radiation. Har ila yau, masana'antun mu suna mai da hankali kan kauri ganuwar PTH wanda ke ba da fa'idodi da yawa ta hanyar rage ƙidayar Layer da rage rashin ƙarfi, bugun ƙafa, da farashin masana'anta gabaɗaya. Muna alfahari da kasancewa ɗaya daga cikin mafi araha da inganci masana'antun PCBs masu nauyi na Copper a duk faɗin duniya.

Koyaya, waɗannan PCBs sun haɗa da tsada fiye da PCBs na yau da kullun kamar yadda tsarin etching yana da ƙarfi da wahala. Ana buƙatar kawar da babban adadin tagulla yayin aikin Etching. Hakanan, tsarin lamination yana buƙatar amfani da Prepreg tare da babban abun ciki na guduro don cike sarari tsakanin alamun jan karfe. Don haka, farashin masana'antu ya fi PCBs na yau da kullun. Duk da haka, muna amfani da hanyar haɗin Blue Bar da Hanyar Copper Copper don samar muku da babban allo a mafi kyawun farashi.

Aikace-aikacen PCBs masu nauyi na Copper

Muna kera kuma muna ba da waɗannan PCBs a inda ake yawan fallasa kai tsaye ko kwatsam zuwa ƙaƙƙarfan zafin yanzu da haɓaka. Irin waɗannan matsananciyar matakan sun isa su lalata PCB na yau da kullun da kira don buƙatun ƙarfe mai nauyi wanda kuma yana rage ƙidayar Layer, yana ba da ƙarancin ƙarfi, kuma yana ba da ƙaramin sawun ƙafa da babban tanadin farashi. A ƙasa akwai wasu wurare da aikace-aikace waɗanda ake amfani da PCBs masu nauyi a cikin:

• Tsarin Rarraba Wutar Lantarki

• Modulolin Amplifier Power

• Akwatunan Rarraba Wutar Mota

• Kayan Wutar Lantarki don Tsarin Radar

• Kayan aikin walda

• Tsarin HVAC

• Aikace-aikacen wutar lantarki

• Kariya da Rigakafin Relays

• Tsarin Lantarki na Railway

• Masu kera Tashoshin Rana

A cikin 'yan shekarun nan, buƙatun waɗannan PCBs ya ƙaru a cikin Automotive, Soja, kwamfuta, da aikace-aikacen sarrafa masana'antu. Kangna yana da shekaru da yawa na gwaninta wajen samar da PCBs masu nauyi na Copper na inganci. ƙwararrun Injiniyoyinmu sun sadaukar da kai don saduwa da mafi girman matsayi da ƙirƙirar kwamitocin Premium waɗanda suka dace da tsammanin ayyukanku da burin riba. Mun fahimci cewa ƙirar PCB mai nauyi ta zo tare da ƙarin hadaddun abubuwa don haka, muna magance duk tambayoyi da damuwa sosai kafin ci gaba da samarwa.

Abin da ya sa mu na musamman shi ne cewa allunan da aka haɓaka suna wucewa ta hanyoyi daban-daban na duba ingancin kafin a kai ga abokan cinikinmu. Sashen kula da ingancin mu na cikin gida yana ba da garantin ingancin PCBs mai nauyi na Copper kuma yana tabbatar da cewa samfurin ƙarshe ya dace da mafi kyawun inganci ba tare da ƙarancin gazawar da'ira ba.

KASHIN KYAUTA

Mayar da hankali kan samar da mafita na mongpu na shekaru 5.